-

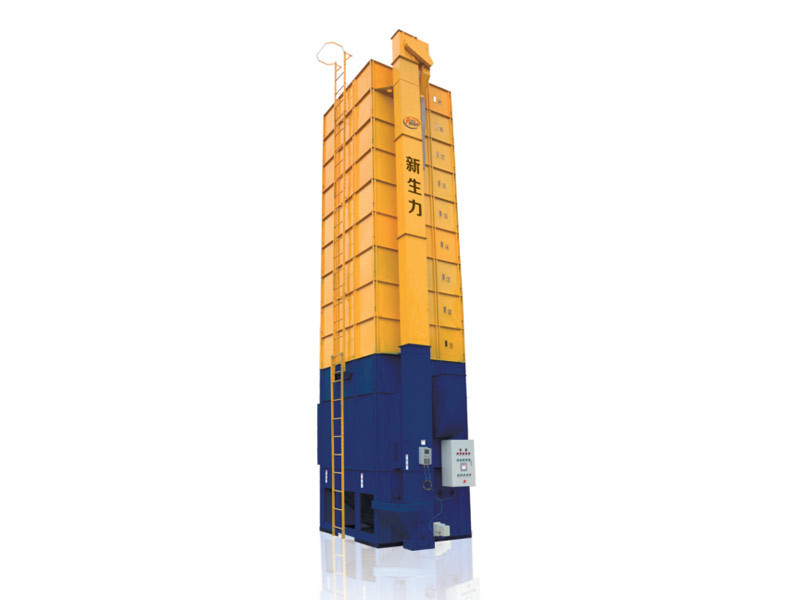

Xinshengli Grain Dryer 5HPX-20C

The 5HPX-20C low-temperature batch circulation grain dryer adopts a new auger-free design and a flow tube type grain inlet and outlet, which reduces the broken rice rate during the grain drying process, saves energy consumption and reduces the equipment failure rate. Fully automatic control design, simple operation, fully automatic moisture detector, accurate control of grain moisture point, to ensure grain drying effect. Suitable for drying rice, wheat, corn, sorghum, and various types of grain seeds.

Parameter configuration

Dryer model 5HPX-20C Dryer type batch cycle Drying capacity t.%/h ≥13 (rice, wheat) Processing capacitykg/h ≥960 Capacity(t) Rice (bulk weight 560kg/m³) 20 Wheat (test weight 700kg/m³) 27.5 Volume m³ 37.2 The weight of the whole machine is about (kg) 4500 Machine ruler Dryer body: 2173X2574X10917 Overall dimensions: 4045X4640X12872 burner Model indirect Ignition mode artificial ignition Fuel consumptionkg/h ≤50(coal) use fuel Biomass (rice husk, straw, firewood), coal Supporting power supply Three-phase 380V/50HZ Supporting power Total power(kW) 10.686 performance Feeding time Rice/wheat(min) 50-60/50-60 Laying time Rice/wheat(min) 50-60/50-60 hourly precipitation rate Rice/wheat(%/h) 0.6-1.2/0.6-1.2 Security configuration Safety protection devices, temperature control devices, electrical overload protection devices, leakage protection devices, fire-fighting equipment.

Efficient and reliable grain drying is a cornerstone of modern agricultural operations, ensuring high-quality yields, reduced post-harvest losses, and safe storage. Our advanced grain drying equipment offers a comprehensive solution for farms, cooperatives, and industrial grain processors seeking to enhance productivity while preserving the integrity of their crops. Designed for versatility, these systems accommodate a wide variety of grains, including wheat, corn, rice, soybeans, and other cereals, delivering consistent drying results across large batches. The equipment employs advanced airflow technology and precise temperature control to achieve uniform drying, preventing common issues such as cracking, uneven moisture content, and nutrient loss. Energy efficiency is a key advantage, as these systems are engineered to minimize fuel or electricity consumption while maximizing drying output, helping operators reduce operational costs and environmental impact. The durable construction ensures long-term performance, using high-quality materials that withstand continuous operation and demanding agricultural environments. Grain drying equipment also simplifies the workflow for operators: automated controls, adjustable settings, and user-friendly interfaces allow precise management of drying cycles, optimizing both speed and quality. By implementing these systems, operators can resolve pain points associated with traditional drying methods, including prolonged drying times, inconsistent results, and high labor requirements. The flexibility of the equipment allows it to be integrated into existing production lines or used as a standalone solution, making it suitable for farms of all sizes. Ultimately, this grain drying equipment helps operators enhance efficiency, preserve crop quality, and increase profitability, providing a reliable and scalable solution for modern agriculture.

Key words:

5HPX-20C