-

Xinshengli Grain Dryer 5HPX-20B

The fully automatic control design is simple to operate and has low production costs; automatic alarm for errors, automatic diagnosis of error points, and automatic grain feeding design; extra-large drying layer to shorten drying time; extra-large elevator to shorten grain feeding time; 5HPX-20B low-temperature batch cycle grain dryer is suitable for drying grains such as wheat, rice, corn, melon seeds, cotton seeds and bean seeds.

Parameter configuration

Dryer model

5HPX-20B

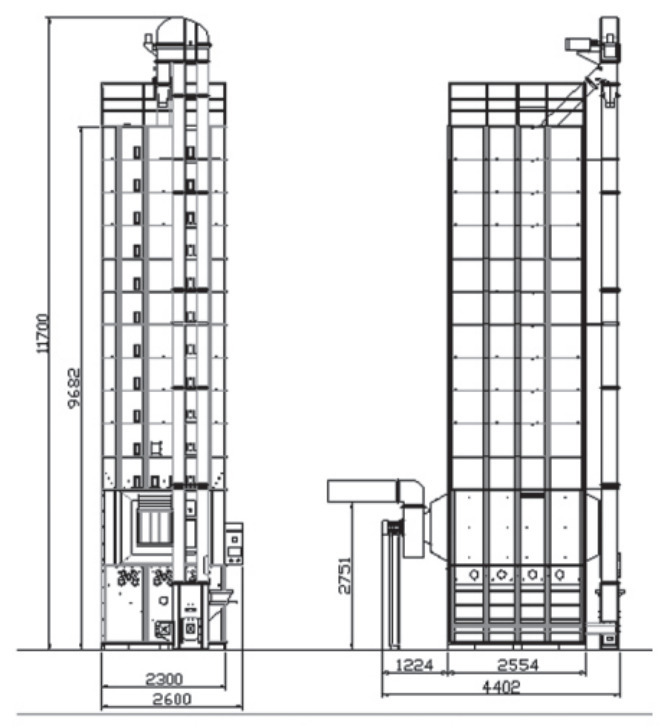

Dryer type Batch cycle Drying capacity t.%/h ≥13(rice, wheat) Processing capacity kg/h ≥960 Capacity (t) Rice (bulk density 560kg/m³) 22 Wheat (bulk density 700kg/m³) 27.5 Volume m³; 40.3 Machine weight (kg) 4200 Machine Drying machine: 2554X2300X11700 Overall dimensions: 4402X2600X11700 Combustion furnace Type Indirect Ignition method Artificial ignition Fuel consumption kg/h ≤50(coal) Fuel used Biomass (rice husk, straw, firewood), coal Supporting power supply Three-phase 380V/50HZ Supporting power Total power (kW) 9.986 Performance Feeding time Rice/wheat (min) 50-60/50-60 Discharge time Rice/wheat (min) 50-60/50-60 Hourly precipitation rate Rice/wheat (%/h) 0.5-1.2/0.5-1.2 Safety configuration Safety protection device, temperature control device, electrical overload protection device, leakage protection device, fire-fighting equipment.

Structure diagram

In modern grain processing, maintaining grain quality while achieving high drying efficiency is a top priority. Low-temperature batch circulating grain dryers offer an innovative solution to this challenge, combining gentle drying with consistent airflow to ensure minimal grain damage and maximum preservation of nutrients. Designed for both small and large-scale operations, these dryers use a batch circulation method, allowing grains to pass through controlled low-temperature zones while air circulates evenly. This system reduces stress on the grains, preventing cracking, discoloration, and nutrient loss that often occurs with high-temperature drying. One of the main advantages of these dryers is their energy efficiency. By utilizing low-temperature heat and optimizing airflow patterns, they consume less energy while achieving uniform drying across all batches. This not only reduces operational costs but also extends the lifespan of both the machine and the grains themselves. The batch circulation method provides operators with precise control over drying duration and temperature, allowing for customization based on crop type and moisture content. This directly addresses common pain points in grain processing, such as uneven drying, high energy consumption, and product degradation. The design of the dryer also emphasizes ease of maintenance and durability, using high-quality materials to withstand continuous operation. Lightweight yet robust, it ensures safe handling, installation, and long-term reliability. In summary, low-temperature batch circulating grain dryers offer an ideal combination of gentle handling, energy efficiency, and high performance. They help operators maximize grain quality, minimize losses, and optimize processing workflows, making them an indispensable tool in modern agricultural and industrial grain management.

Key words:

5HPX-20B