-

Xinshengli Grain Dryer 5HPX-15

The low-temperature batch-type circulating grain dryer uses a constant temperature ventilation device, an automatic and uniform temperature adjustment method, and indirect heating with hot air from all directions, so that the grains are free of any pollution during the drying process, and the drying temperature is uniform, and the color and smell are excellent. It is an essential artifact for grain drying. The low-temperature batch-type circulating grain dryer is suitable for drying wheat, rice, corn and other legumes and seeds.

Parameter configuration

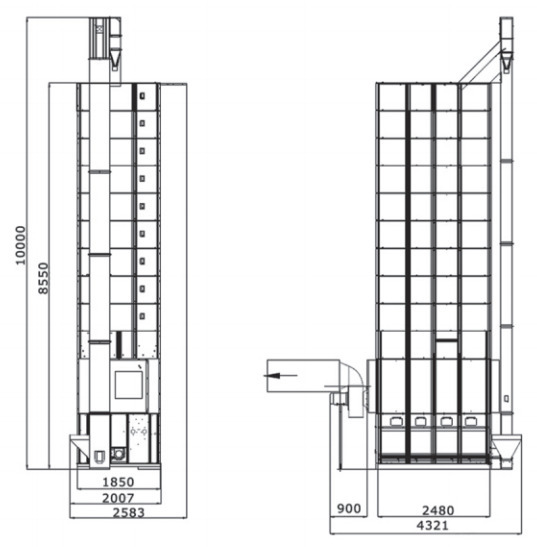

Dryer model 5HPX-15 Dryer type Batch cycle Drying capacity t.%/h 9-11(rice, wheat) Processing capacity kg/h ≥800 Capacity (t) Rice (bulk density 560kg/m³) 15 Wheat (bulk density 700kg/m³) 18 Volume m3; 27 Machine weight (kg) 3075 Machine R Drying machine body: 2007×2480×9010 Overall dimensions: 2583×4321×10000 Combustion furnace Type Indirect type Ignition method Artificial ignition Fuel consumption kg/h ≤60(rice husk) Fuel used Biomass (rice husk, straw, firewood), coal Supporting power supply Three-phase 380V/50HZ Supporting power Total power (kW) 9.95 Performance Feeding time Rice/wheat (min) 80-90/80-90 Discharge time Rice/wheat (min) 80-90/80-90 Hourly precipitation rate Rice/wheat (%/h) 0.5-0.8/0.5-0.8 Safety configuration Safety protection device, temperature control device, electrical overload protection device, leakage protection device, fire-fighting equipment. Structure diagram

In modern agriculture, efficient grain drying is critical for maintaining quality, reducing post-harvest losses, and ensuring safe storage. Our wholesale Grain Dryer Machine offers a comprehensive solution for farms, cooperatives, and industrial grain processing operations. Engineered for speed, uniformity, and energy efficiency, this machine handles large volumes of grains such as corn, wheat, rice, and soybeans, providing consistent drying results that preserve nutritional value and minimize spoilage. Its advanced airflow system ensures even heat distribution, while adjustable temperature and drying duration settings allow operators to customize the process for different grain types and moisture levels. The machine is designed for durability and long-term operation, constructed from high-quality materials resistant to wear, corrosion, and high temperatures. One of the primary advantages is its ability to significantly reduce drying time compared to traditional sun-drying or low-efficiency methods, which translates into faster processing cycles, improved productivity, and reduced labor costs. Many customers have successfully implemented our grain dryer machines to upgrade their production lines. For example, a cooperative in northern China increased its daily processing capacity by 30% while maintaining high-quality grain standards. Another industrial farm in Southeast Asia reported reduced spoilage rates and improved energy efficiency, directly lowering operational costs. Beyond speed and quality, the machine addresses common pain points such as inconsistent drying, grain cracking, and uneven moisture content. With automated controls, precise temperature management, and uniform airflow, the wholesale Grain Dryer Machine ensures that every batch is processed reliably, reducing waste and improving overall profitability. Lightweight in design but robust in construction, it allows easy installation and maintenance, helping operators save time and resources while focusing on core production activities. Whether for small-scale farms or large industrial operations, this machine offers a scalable, dependable, and cost-effective solution to modern grain drying challenges. By choosing our wholesale Grain Dryer Machine, customers gain not only cutting-edge technology but also a trusted partner in maximizing harvest quality and operational efficiency.

Key words:

5HPX-15